Custom Seal Design

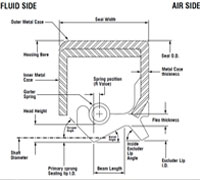

Custom seals are individually designed and optimized for each application, insuring maximum reliability and performance. Custom seals from Clark Seals differ from standard seal designs in that they are precisely engineered for each application using an extensive 144 point evaluation process. Every operational variable is analyzed thoroughly and used to adjust and optimize critical design elements. These elements include features such as case design, beam length, flex thickness, spring position, spring tension, head height, interference, contact width, primary and secondary lip geometry, etc. Custom seals from Clark Seals take approximately 7 days to design, cost the same as standard seal designs, and last approximately 7-10 times longer.

(click on thumbnail to enlarge)

Custom Seal Design

Shaft Seal Diagram

Case Studies

- Custom Designed & Manufactured Viton Shaft Seal for a Snow Blower

- Custom Designed & Manufactured Viton Shaft Seal for a Prosthetic Knee System

- Custom Designed & Manufactured Nitrile Mechanical Seal for a Washing Machine Tub

- Custom Designed & Manufactured Nitrile Transmission Seal for a Vertical Input Shaft

- Custom Designed & Manufactured Nitrile Sheave Seal for the Oil & Gas Industry

Custom Seal Design Capabilities

- General Capabilities

- O.E.M. Supplier

Custom Manufacturing

- Primary Manufacturing Capabilities

-

- Assembly

Molding (64 Machines)

Trimming (16 Machines) - Roll forming (5 Machines)

CNC Turning (4 Lathes)

- Assembly

- Design Capabilities

- Design Optimization

- 144 Point Seal Engineering Process

- Recommendations

- Design for Manufacturability

- Seal Types

-

- Shaft Seals

- Metal Cases

- Rubber Cases

- Garter Spring Equipped

- Mechanical Seals

Bearing Seals

- Shaft Seals

- Materials

-

- Stainless Steel

- Seal Case

- Springs

Nitrile NBR - Saturated Nitrile HNBR

Poly Acrylic

Silicone

Fluoroelastomer

- Stainless Steel

- Tolerance (+/-)

- ±.100 in

- Quality Capabilities

- 12 Stage Inspection & QC Process

- Seal Properties

- Last about 300% Longer than Average when compared to others.

- Seal Characteristics

-

- Bend Resistant

Electrical Insulating

EMI Shielding

Protects from electromagnetic (EMI) interference.

Flame Retardant

Heat Dissipating

Heat Reflective

Low Pressure

Low Temperature - High Pressure

High Temperature

Pipe

RFI Shielding

Protects from radio frequency (RFI) interference.

Ring

Universal

Wrap Around

- Bend Resistant

- Seal Resistances

-

- Abrasion

Acids

Alkalis

Corrosion

Detergents

Grease

- Oil

Rust

Salts

Steam

Spark

Water

- Abrasion

- Production Volume

-

- Min (For Manufacturers)

500,000 Pieces Annually Specialty Production Shop

Prototypes- For Manufacturers to Test before Production Run

- Low Volume

High Volume

Long R un

Short Run

- Min (For Manufacturers)

- Intended Application

-

- Axels

ATV's

Bicycles

Blowers

Chassis

Compressors

Conveyors

Cranes

Crushers

Diesel Engines

Dishwashers

Drills

Elevators

Engines

Escalators

Excavators

Fans

Garbage Disposals - Gearboxes

Grinding Mills

Hoists

Lawn & Garden Equipment

Loaders

Marine Engines

Pipelines

Petroleum Refining

Power train

Screens

Sheaves

Snowmobiles

Steering

Suspension

Transmissions

Washers

Wind Turbines

- Axels

- Industry Focus

-

- Agriculture

Appliance

Automotive

Construction

Heavy Duty Truck

Material Handling - Mining

Power Equipment

Oil & Gas

Recreation

Renewable Energy

- Agriculture

- Industry Standards

- ANSI - American National Standards Institute

ASTM - American Society for Testing and Materials

CE - The CE mark (officially CE marking) is a mandatory conformity markon many products placed on the single market in the European Economic Area(EEA).

DOT - Department of Transportation

FDA - Food And Drug Administration

ISO - International Organization for Standardization- ISO 9001:2008

RMA - Rubber Manufacturers Association- Manufacture to RMA Standards

TS - Technical Specifications, used with ISO

UL - Underwriters Laboratory

- File Formats

- AutoCAD (DWG)

BMP - Bit Mapped Graphics

DXF - Drawing Interchange Format, or Drawing Exchange Format

GIF - Graphics Interchange Format

JPG or JEPG - Joint Photographic Experts Group

PDF - Portable Document Format

TIFF - Tagged Image File Format

Print This Page

Print This Page